Introduction

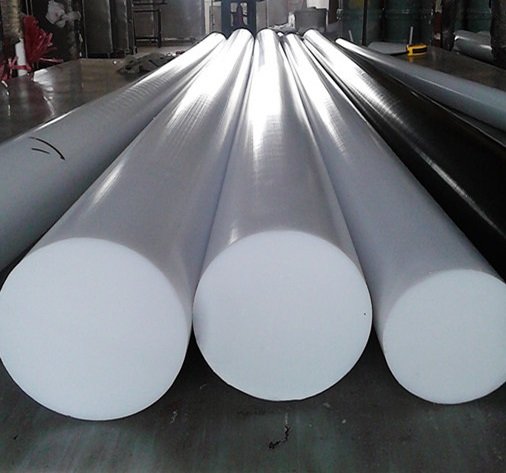

PTFE molded sheet is manufactured by molding method with PTFE granular resin. In fluoroplastics, PTFE got the most consumption and was used widely. It’s an important material in a variety of fluoroplastics. PTFE exhibits astonishing chemical resistance. This self-lubricating material provides a low friction coefficient and is ideally suited for the manufacture of corrosion-resistant gaskets & seals.

Features:

- Temperature resistance —It is able to work stably between -180°C to +260°C.

- Excellent chemical corrosion resistance —Applicable medium includes oil, acid solution, and almost all chemical materials.

- Excellent non-sticky property – –With a low friction coefficient, it is easier to remove those resin, dopes, oil, and other sticky things.

- Anti-aging, weathering resistance.

- Excellent insulation property.

- Filled material: Filled PTFE products has a more outstanding performance by adding filler such as carbon, graphite, bronze, glass fiber, carbon fiber, MOS2, PEEK, PI, POB BaSO4, SiO2, glass bead, polyamide.

Specification:

The General Specification of PTFE Rod:

| OD(mm) | Length(mm) | Length(mm) |

| 1, 2, 3, 4 | continuous length | |

| 5, 6, 8, 10, 12, 15, 16, 18, 20, 22, 25, 28, 30, 32, 35, 40 | 1000 | 2000 |

| 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 100 | 1000 | 2000 |

| 110, 120, 130, 140, 150, 160, 170, 180, 190, 200 | 1000 | 2000 |

Custom specifications of PFFE Rod:

| Item | Dia.(mm) | Length(mm) |

| Paste Extruded Rod | 1~4 | According to customer’s request |

| Plug Extruded Rod | 4~200 | 500~2000 |

Gallery:

Reviews

There are no reviews yet.